Explaining the Laboratory Roll-to-Roll Coater

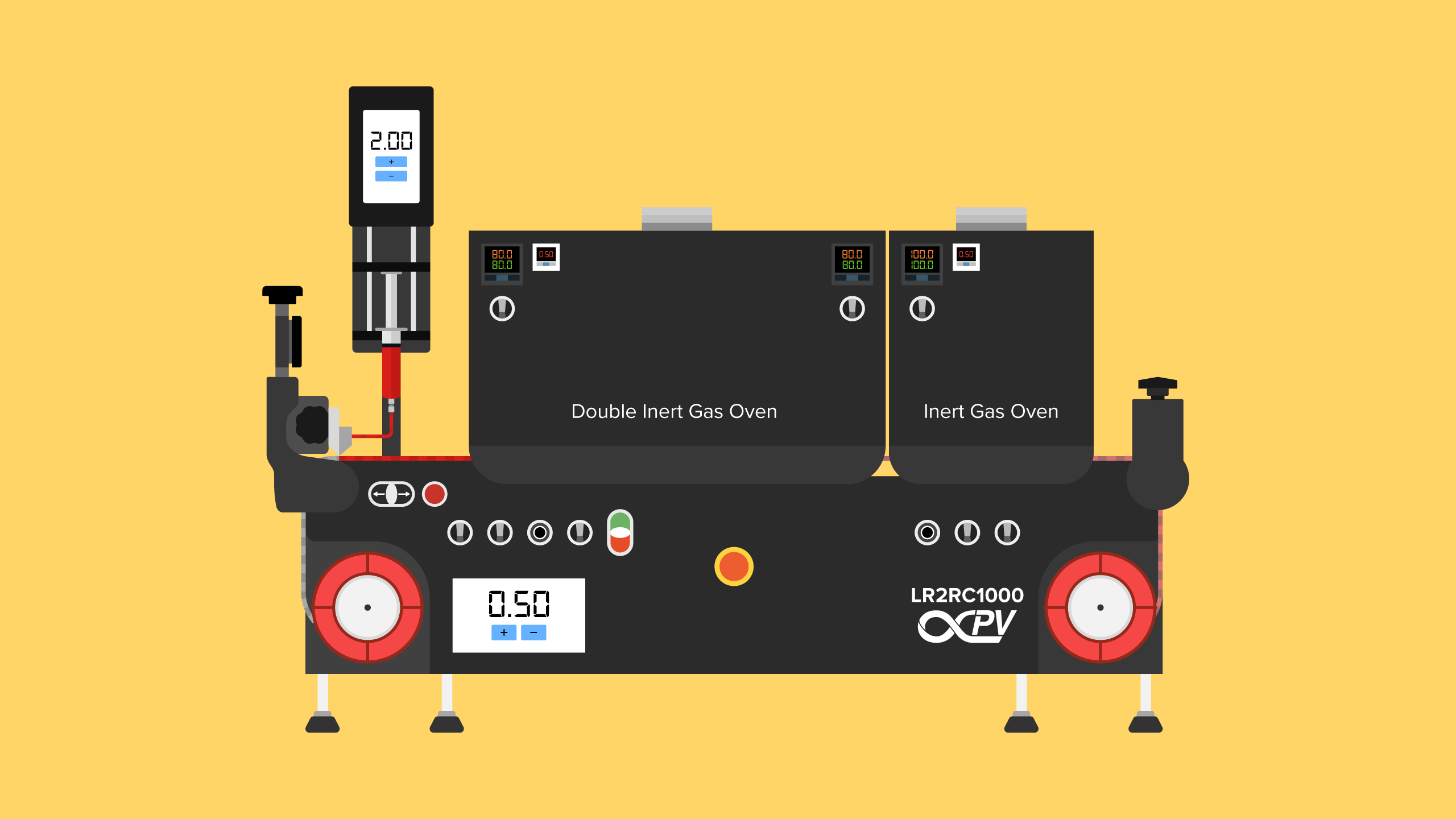

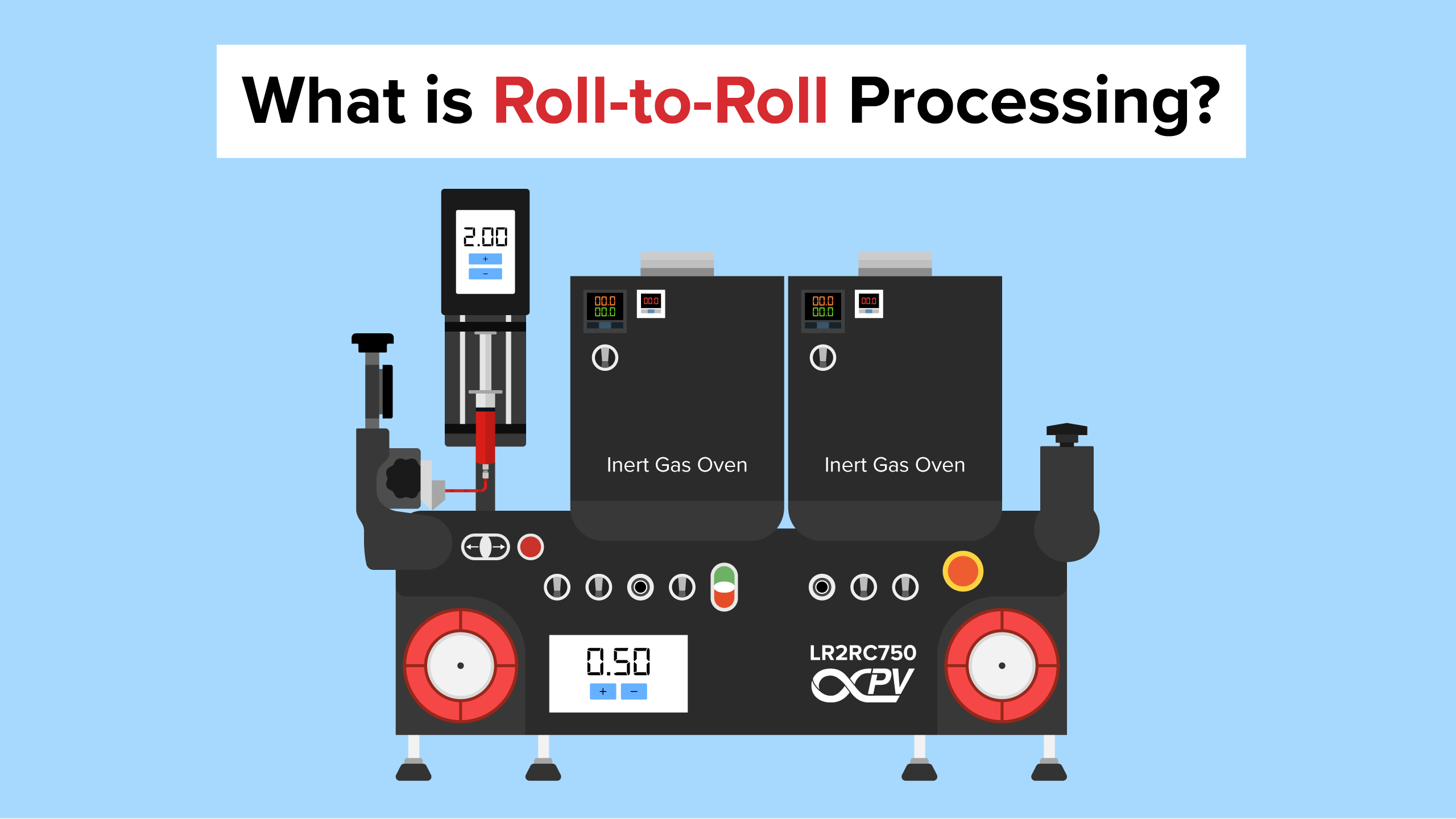

How do you explain a machine that can be customized in thousands of different ways, fits inside a fume hood, and is able produce both solar cells, batteries and OLEDs? The Laboratory Roll-to-Roll Coater is a modular platform for coating and printing functional thin films. It is compact, highly flexible, and unlike many similar systems, it is designed to be customized down to the smallest detail. While its capabilities are extensive, the modularity and compact footprint can make it difficult to visualize, especially when comparing the different platform sizes and possible component configurations.

To communicate the unique capabilities of the Laboratory Roll-to-Roll Coater, I developed a technical animation that clearly illustrates how the system is designed and operated. Based on accurate technical drawings, every platform and component are shown to scale. The animation highlights the system’s key features, including available platform lengths and web widths, and demonstrates how it integrates seamlessly into laboratory environments such as fume hoods and gloveboxes. It also showcases the extensive range of compatible modules emphasizing the flexibility to configure the system according to specific research or production requirements. In addition, the animation outlines the main application areas, from printed solar cells and batteries to transistors, OLEDs, and sensors, while demonstrating the system’s ability to process thin-film materials with exceptional precision and repeatability.

The outcome is a clear, engaging and fast overview that can help researchers, engineers, and purchasing managers visualize how the system fits their specific setup. Whether a user is working on perovskite solar cells in a glovebox or scaling up a battery process on a lab bench, the animation helps them imagine how the coater can be built to meet their specific needs.